Diavel Wïngs

Aerodynamics . . .

Used to lift people off the ground since 1903, and used to push tires into the ground since 1967. However, motorcycles have been lagging far behind cars in the downforce department. Perhaps it is because nobody thought it would be applicable to two-wheeled, leaning machines. But recent times have proved otherwise.

Ducati was the first to apply winglets to their MotoGP bike in 2015, and their street bike based WorldSBK entry in 2019. Recognizing the competitive advantage of downforce, other manufacturers have quickly got up to speed. Currently, all MotoGP bikes run downforce producing arrangements, and on the street bike side of things, Aprilia, MV Agusta, Honda, and BMW have some form of winglet arrangement.

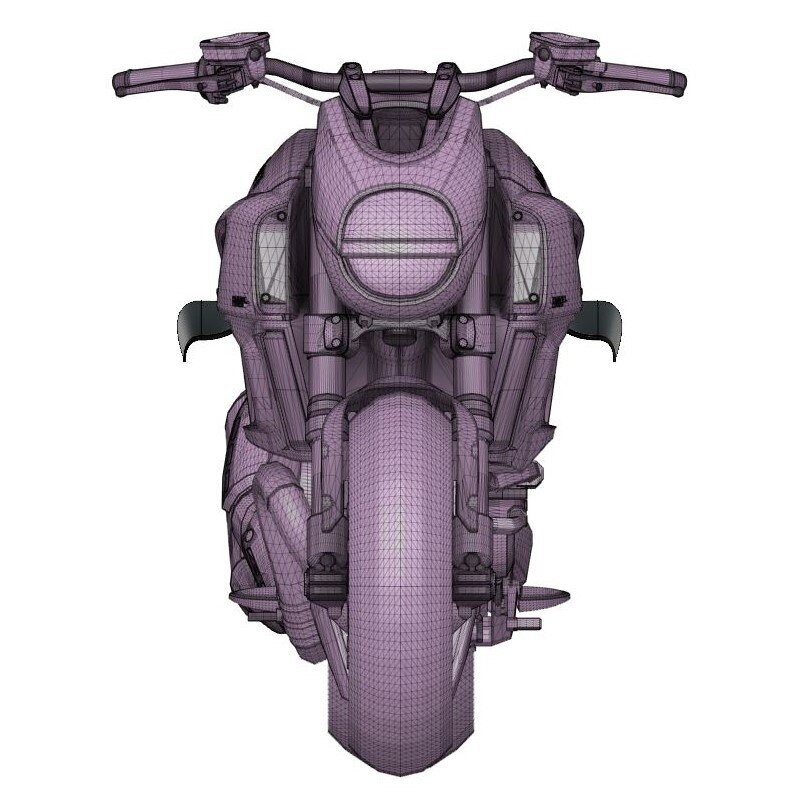

However, my motorcycle, a 2012 Ducati Diavel, was made years before this aerodynamic revolution. But, I’m a big fan of this technology, and so I was determined to figure out a solution. The goal is to make around the same downforce numbers as the other manufactures without making them obnoxiously large/ugly. Luckily, I found an STL file for the bike online, dragged it into Fusion 360, and began experimenting. After a few iterations, I arrived at the shape you see below.

I was able to simulate them, using SimScale, to find the right balance of size and performance. The final version, in the simulation space, make an additional 12lbs of downforce at 100mph. It may not sound like much, but comparing the numbers to the V4R, which makes a claimed 66 lbs. at 168mph, these wings making 53 lbs. at the same speed. Only 13 lbs. off of Italy’s best!

Graphed below are all of the published downforce numbers from the other manufacturers.

Note: Only one advertised value exists for the V4R, Streetfighter, V4 Superleggera, RSV4, and M 1000 RR, so values are added at the 100mph mark to create the exponential fit lines. They are there for reference only.

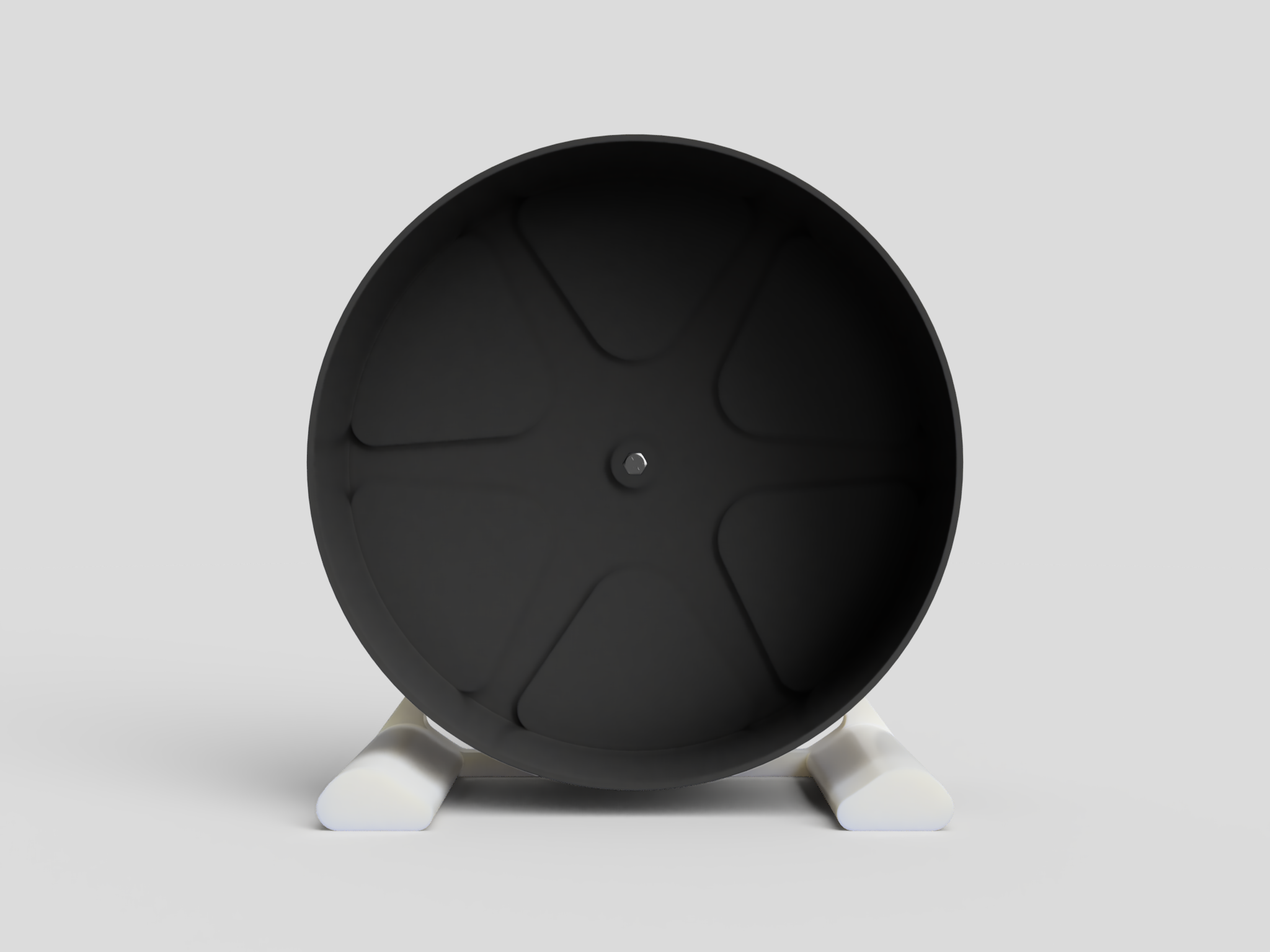

Once the design was complete, it was time for prototypes. Ultimately, many test pieces were needed, as the STL file was not perfectly scaled. It took three wing files that were 3D printed in PLA to get the fit just right. The final version was then printed in tough resin and painted to have a similar finish as the rest of the black plastic on the bike.

One day, and 3 trips to the hardware store later, the final wings are finally assembled. They are attached to the trellis frame, using 3D printed two-piece clamps with metal threaded inserts, making them very secure. Unfortunately, winter is upon us, so I’ll have to bundle up to see these wings flapping in the wind. Will I be able to tell a difference? Definitely not a street speed. But, the mission has been accomplished, and I think they look pretty rad. What do you think?